GISS Forum 2018, Shenzhen, China

The First International GISS Technology Forum (GISS Forum) was held in Shenzhen, China, on October 25, 2018.

After 15 years of development, the benefits of the GISS slurry casting process are now taking hold in the industry.

In live tests at casting operations in Asia and Europe, GISS Technology has demonstrated success in reducing porosity in cast parts, reducing the number of rejected parts, extending die life, and reducing energy and lubricant use.

Looking to the future, GISS Technology promises to transform die casting applications in automotive, telecommunications, and consumer electronics with the opportunity to create lighter products with the same strength and better surface finish.

At GISSCO, we believe we are at an inflection point for the industry and that the adoption of GISS Technology will increase geometrically over the next few years.

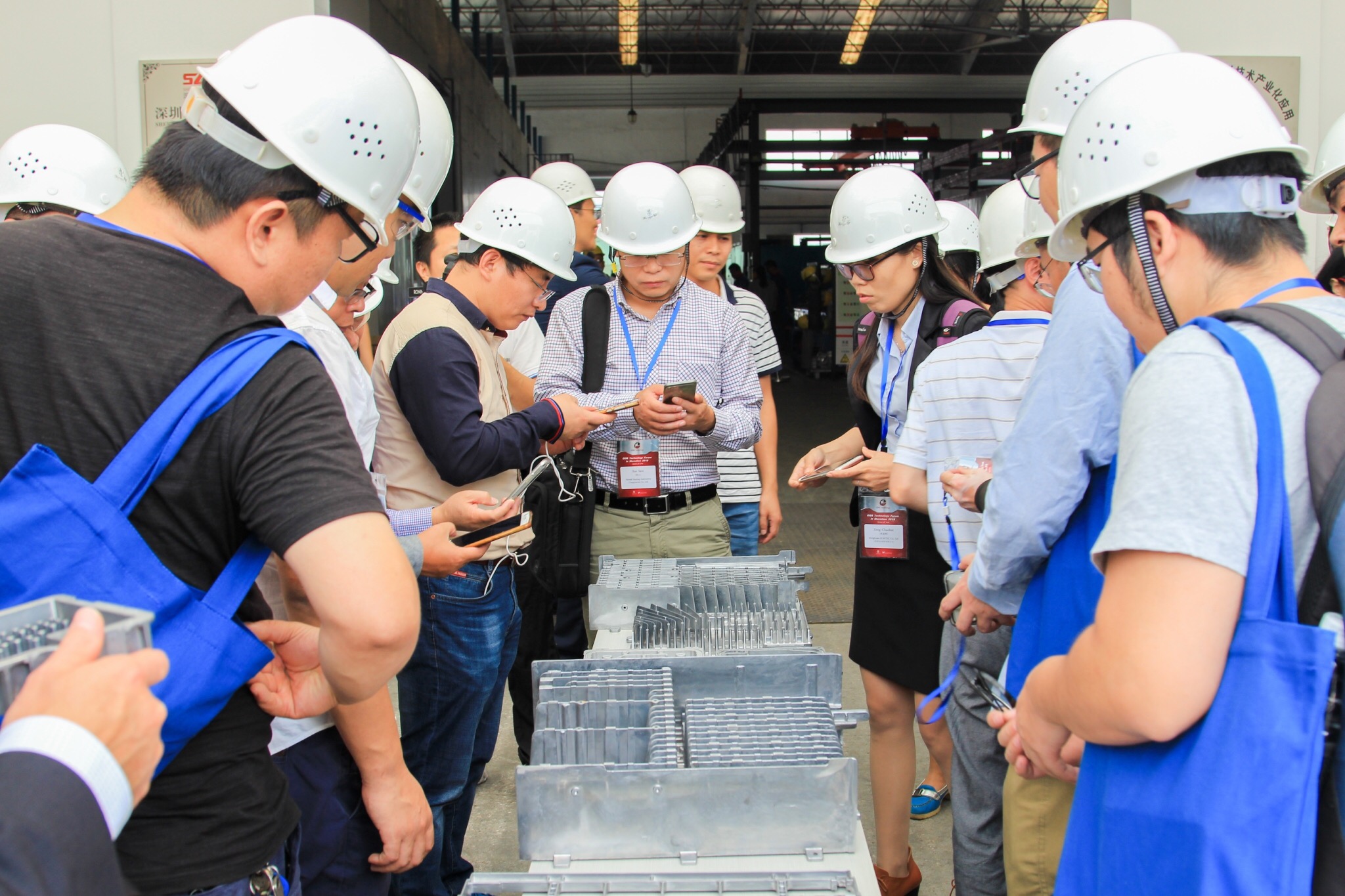

Given this potential, GISSCO set up a meeting of die casting leaders from around the world to discuss the success of GISS Technology and share ideas about its future potential. The meeting was held in Shenzhen on October 25, 2018.

This meeting highlighted:

- Several successful GISS use cases and some of their results.

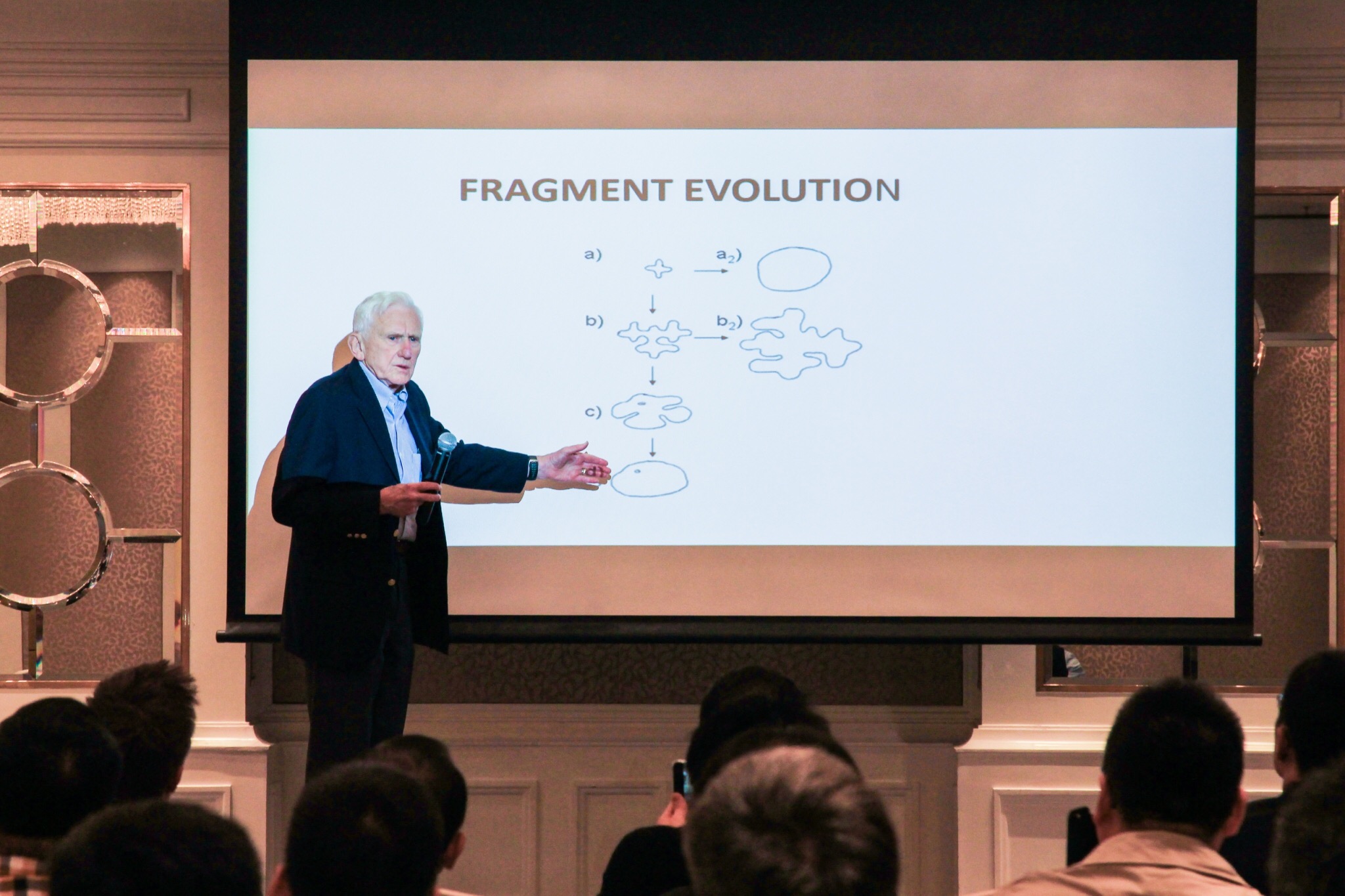

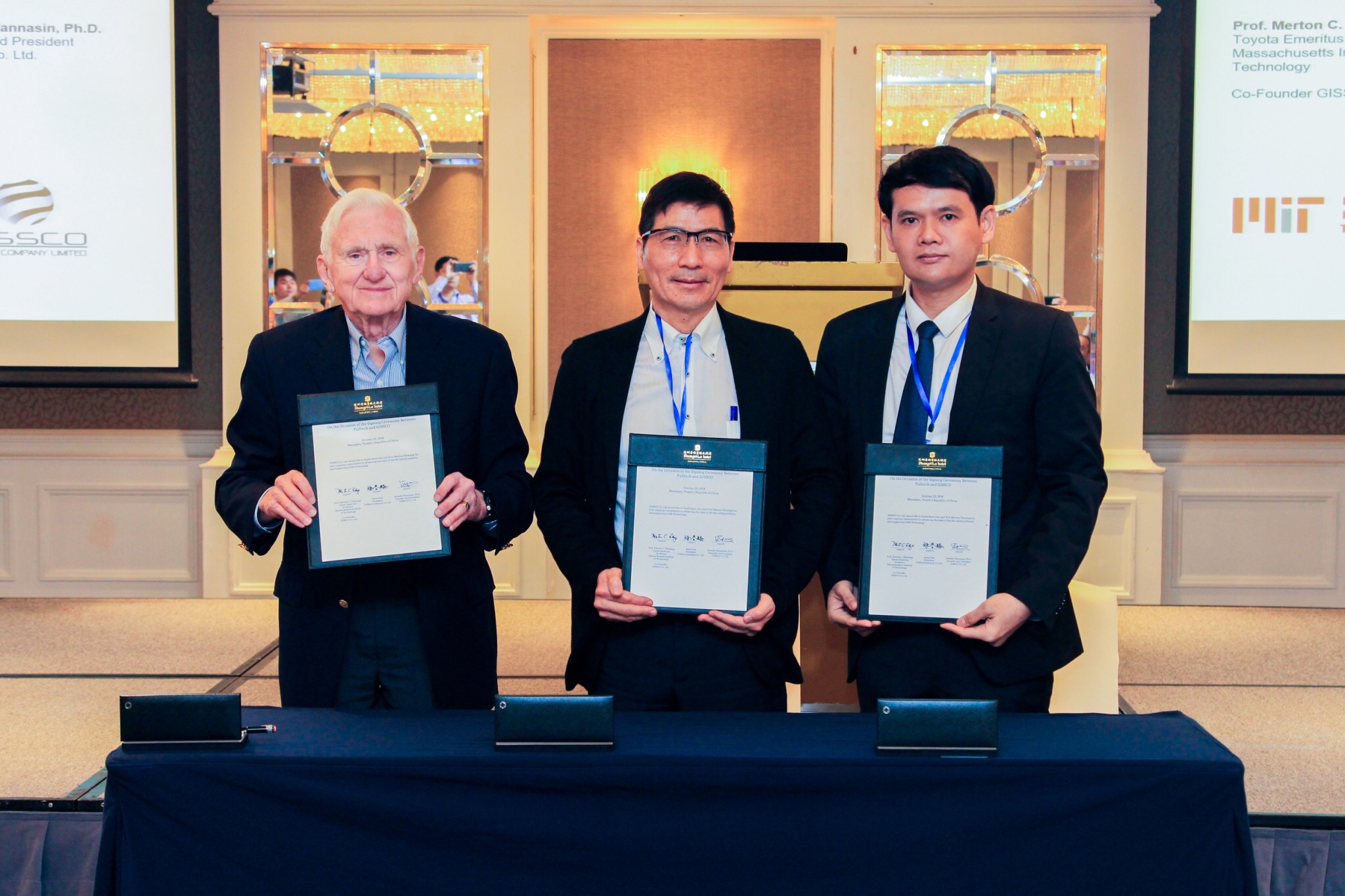

- Prof. Merton Flemings, the grandfather of semi-solid metal processing, delivered a keynote address on how GISS and slurry casting will transform die casting.

- Jessada Wannasin, founder of GISSCO, provided an update on the state-of-the-art GISS Technology.

- Marc Fuchs, Director of Global Application Technology Die Casting at Buhler Group, discussed the results of Buhler’s tests of GISS Technology and its potential applications.

- Representatives from the automotive and consumer products industries discussed their experiences testing GISS applications.

The latest paper explaining GISS Technology in detail can be downloaded here: S2P2018-GISS-wannasin.pdf.