GISS Technology enhances casting quality while simultaneously reducing production costs by using the Superheated Slurry Casting Process, the latest innovation in metal casting.

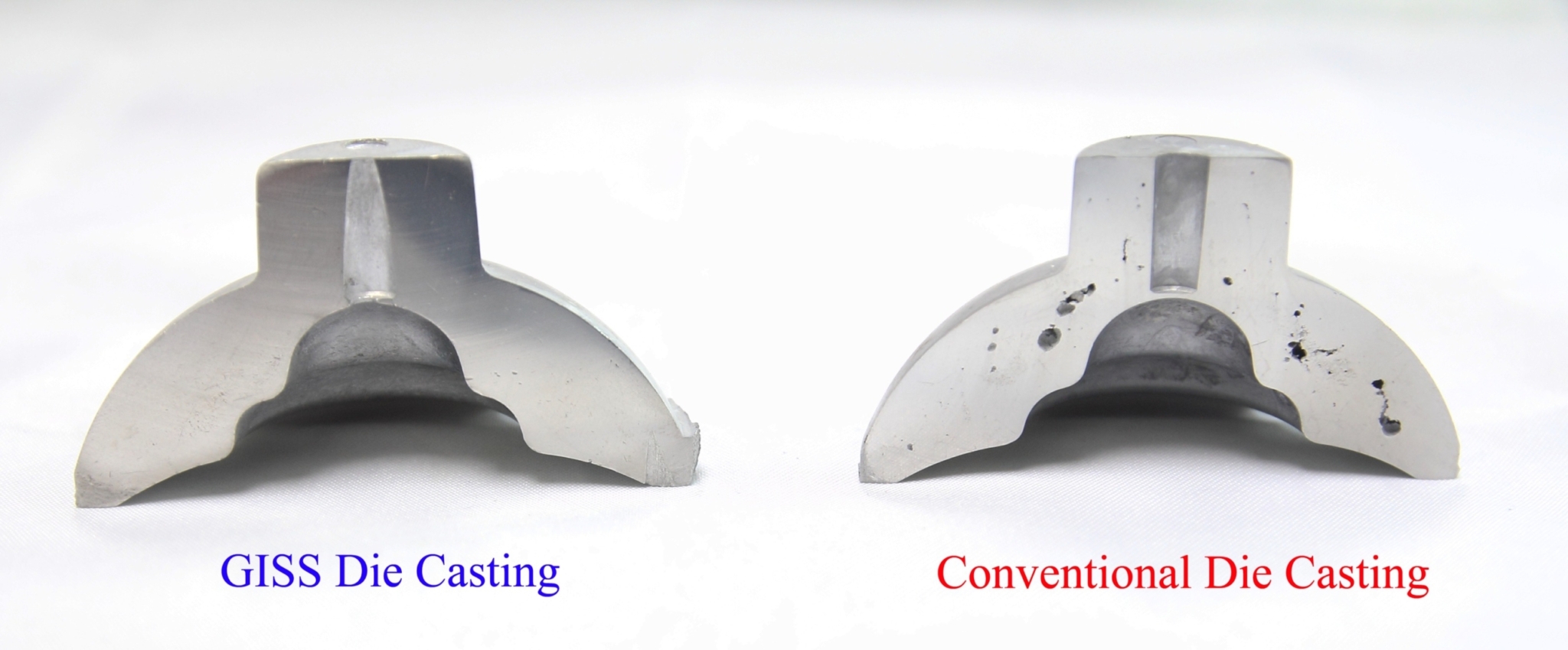

This patented technology provides a quick solution for die casters facing porosity defects and high reject rates. Unlike other methods like vacuum assist and squeeze pins, GISS Technology also reduces production costs. Our customers benefit from significant production cost reductions with its application.

In addition to improving quality and lowering costs, GISS Technology enables the casting of wrought aluminum alloys such as 6061, 6063, and 7075, which can be anodized. This breakthrough opens up new opportunities in the die casting industry.

More information about GISS Technology can be downloaded here: GISS Technology Company Profile

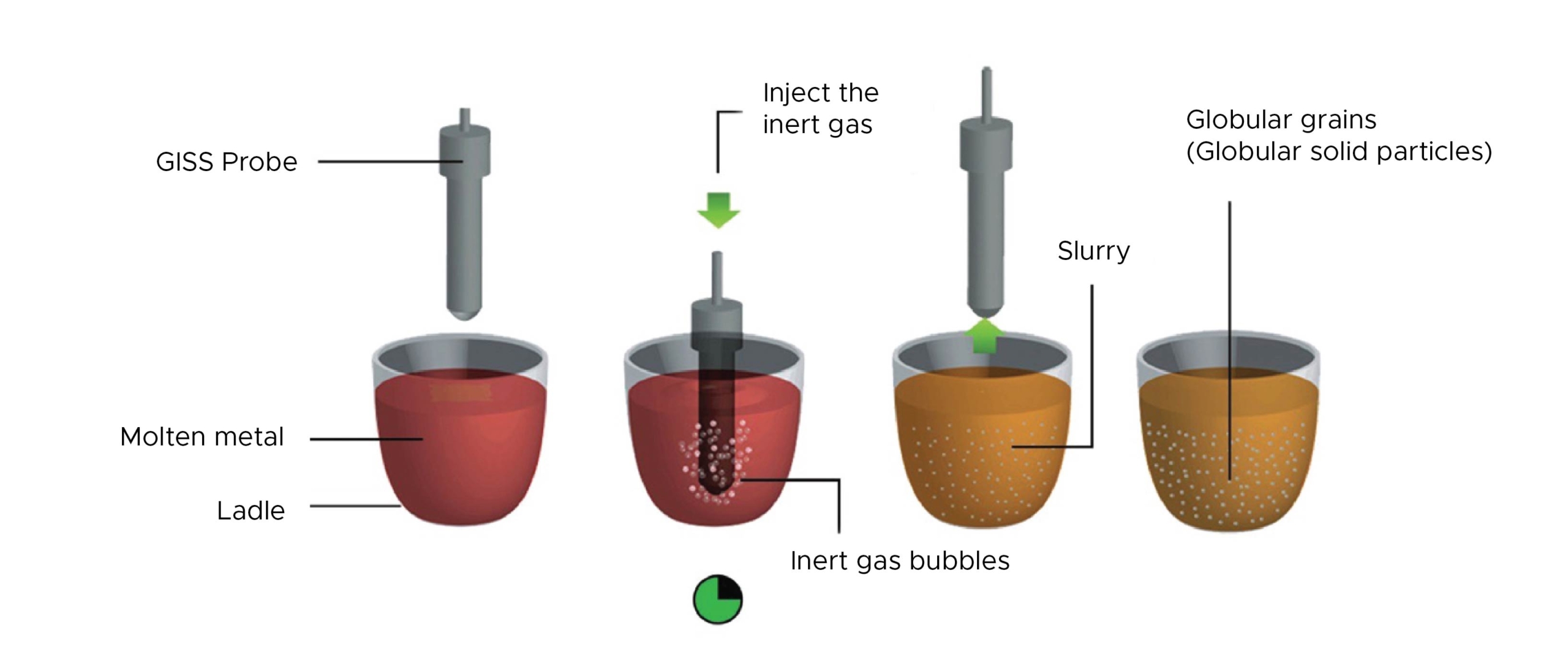

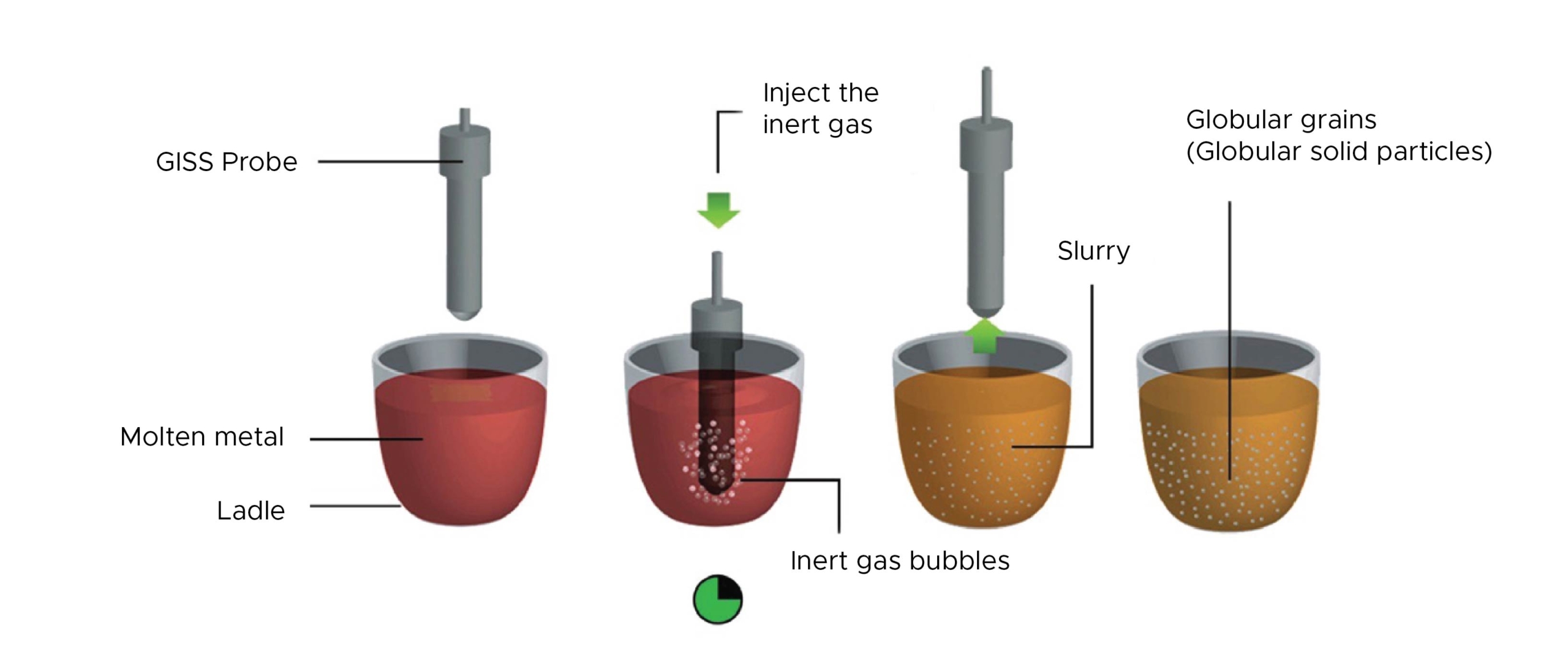

Superheat Slurry Casting Process

By injecting micro-sized inert gas bubbles into the liquid metal, GISS Technology converts it into superheated slurry, which effectively fills die cavities with lower heat content. This results in cost benefits like extended die life and reduced cycle time. The controllable solid fraction in the slurry allows precise flow control, reducing gas porosity and shrinkage porosity due to pre-existing solid particles.

GISSCO integrates GISS Units into existing production setups, using current die casting machines and dies, and provides full technical support, optimizing die casting parameters without needing modifications to existing die designs.

01

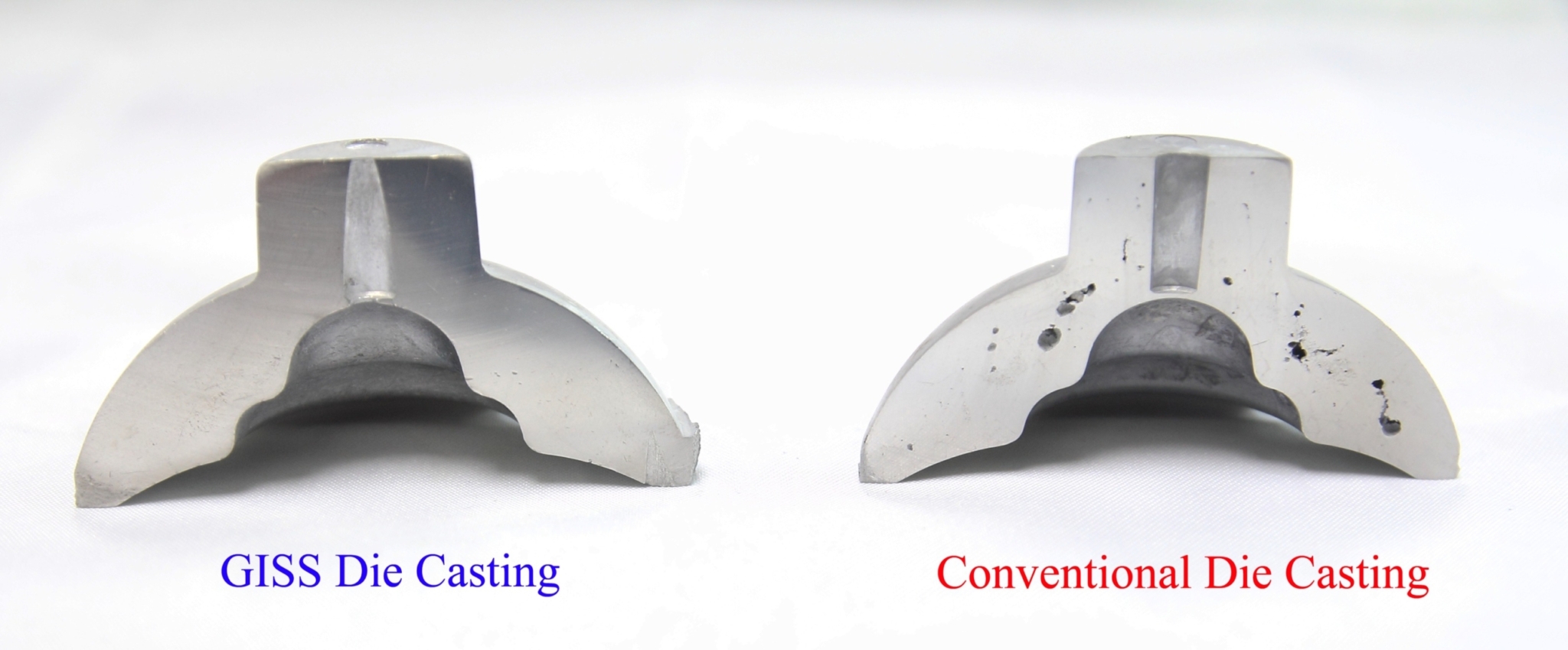

Gas porosity reduction

Controlled solid fraction in the slurry reduces turbulent flow compared to conventional high-pressure die casting, thereby reducing gas porosity.

03

Shrinkage porosity reduction

Initial solid particles in the slurry act as nucleation sites, altering solidification and reducing shrinkage porosity.

02

Shrinkage porosity reduction

Initial solid particles in the slurry act as nucleation sites, altering solidification and reducing shrinkage porosity.

04

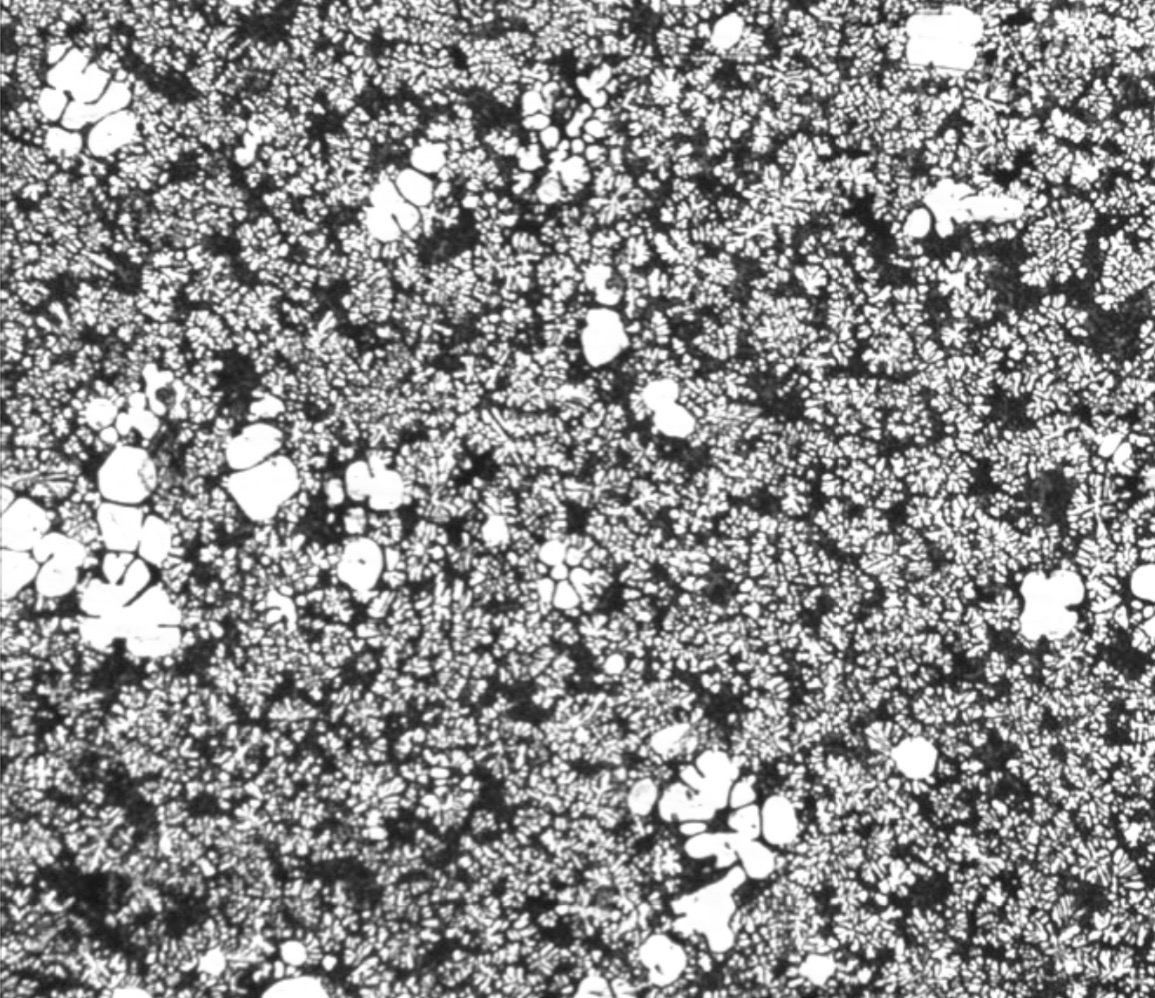

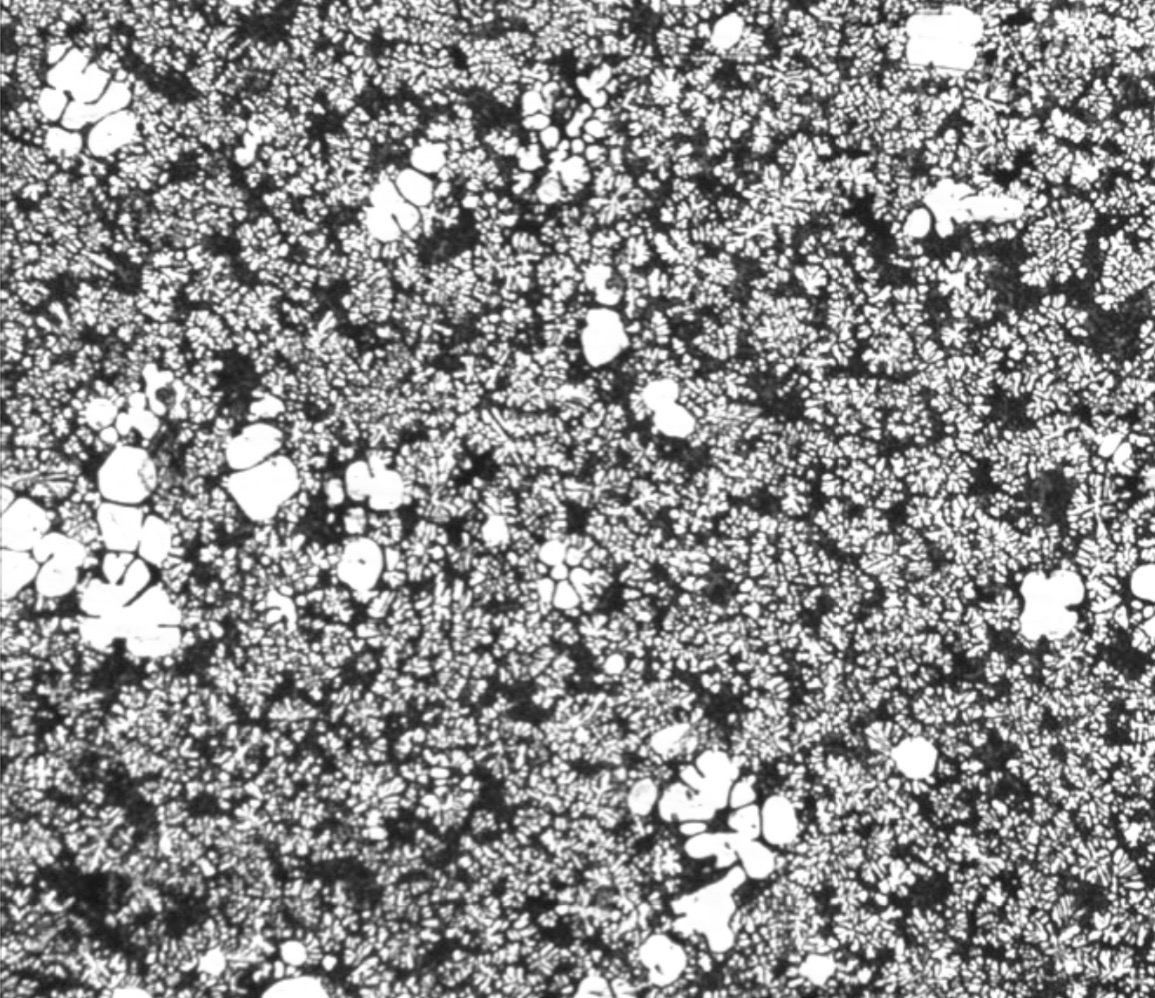

Ultra-fine solid particles

These facilitate easy flow into ultra-thin sections and promote a uniform microstructure.

By injecting slurry with lower heat content, controlled viscosity, and initial nuclei, GISS Technology achieves immediate cost benefits.*

- Reject rate reduction due to gas porosity and shrinkage porosity from 10-50% to 1-5%

- Production cost reduction by 5-10%

- Cycle time reduction by 15-25%

- Increased die life by 2-4 times

- Melting energy, lubricant usage, and water treatment reduction by 15-30%

*Actual savings and benefits vary by application. Generally, our customers achieve a payback period of about 6-12 months on their investment in GISS Technology.

Machine Sizes: 125-T to 2,500-T

Electronic and Automotive Parts: 0.1 kg to 20 kg parts

Forming Processes

High-Pressure Die Casting

In the GISS high-pressure die casting process, the high-pressure die casting machine and process cycle remain largely unchanged from conventional high-pressure die casting. The only added step occurs during the ladle transfer when a diamond probe is immersed. Therefore, no significant modifications are needed for existing high-pressure die casting equipment.

Squeeze Casting

Adding the GISS process to create semi-solid slurry before squeeze casting is very simple. This process results in high density, near-zero porosity, heat-treatable, and high mechanical properties.

Gravity Casting

GISS slurry casting under gravity pressure produces finer, more uniform grain structures with less shrinkage porosity. This process shortens solidification time by 40%, resulting in significant cycle time savings, improved mechanical properties, and better casting yield.

All Metals and Alloys

GISS Technology can process pure aluminum, copper, silver, gold, and other metals, as well as a wide range of commercial alloys including aluminum, magnesium, zinc, copper, lead, tin, and iron. In fact, all metals and alloys can be effectively processed with GISS Technology.

Superheat Slurry Casting Process

By injecting micro-sized inert gas bubbles into the liquid metal, GISS Technology converts it into superheated slurry, which effectively fills die cavities with lower heat content. This results in cost benefits like extended die life and reduced cycle time. The controllable solid fraction in the slurry allows precise flow control, reducing gas porosity and shrinkage porosity due to pre-existing solid particles.

GISSCO integrates GISS Units into existing production setups, using current die casting machines and dies, and provides full technical support, optimizing die casting parameters without needing modifications to existing die designs.

01

Gas porosity reduction

Controlled solid fraction in the slurry reduces turbulent flow compared to conventional high-pressure die casting, thereby reducing gas porosity.

02

Shrinkage porosity reduction

Initial solid particles in the slurry act as nucleation sites, altering solidification and reducing shrinkage porosity.

03

Shrinkage porosity reduction

Slurries enter the die with lower heat content, resulting in shorter cycle times and extended die life.

04

Ultra-fine solid particles

These facilitate easy flow into ultra-thin sections and promote a uniform microstructure.

By injecting slurry with lower heat content, controlled viscosity, and initial nuclei, GISS Technology achieves immediate cost benefits.*

- Reject rate reduction due to gas porosity and shrinkage porosity from 10-50% to 1-5%

- Production cost reduction by 5-10%

- Cycle time reduction by 15-25%

- Increased die life by 2-4 times

- Melting energy, lubricant usage, and water treatment reduction by 15-30%

*Actual savings and benefits vary by application. Generally, our customers achieve a payback period of about 6-12 months on their investment in GISS Technology.

Machine Sizes: 125-T to 2,500-T

Electronic and Automotive Parts: 0.1 kg to 20 kg parts

Forming Processes

High-Pressure Die Casting

In the GISS high-pressure die casting process, the high-pressure die casting machine and process cycle remain largely unchanged from conventional high-pressure die casting. The only added step occurs during the ladle transfer when a diamond probe is immersed. Therefore, no significant modifications are needed for existing high-pressure die casting equipment.

Squeeze Casting

Adding the GISS process to create semi-solid slurry before squeeze casting is very simple. This process results in high density, near-zero porosity, heat-treatable, and high mechanical properties.

Gravity Casting

GISS slurry casting under gravity pressure produces finer, more uniform grain structures with less shrinkage porosity. This process shortens solidification time by 40%, resulting in significant cycle time savings, improved mechanical properties, and better casting yield.

All Metals and Alloys

GISS Technology can process pure aluminum, copper, silver, gold, and other metals, as well as a wide range of commercial alloys including aluminum, magnesium, zinc, copper, lead, tin, and iron. In fact, all metals and alloys can be effectively processed with GISS Technology.